- #How to use mach3 cnc software how to#

- #How to use mach3 cnc software upgrade#

- #How to use mach3 cnc software windows 10#

- #How to use mach3 cnc software software#

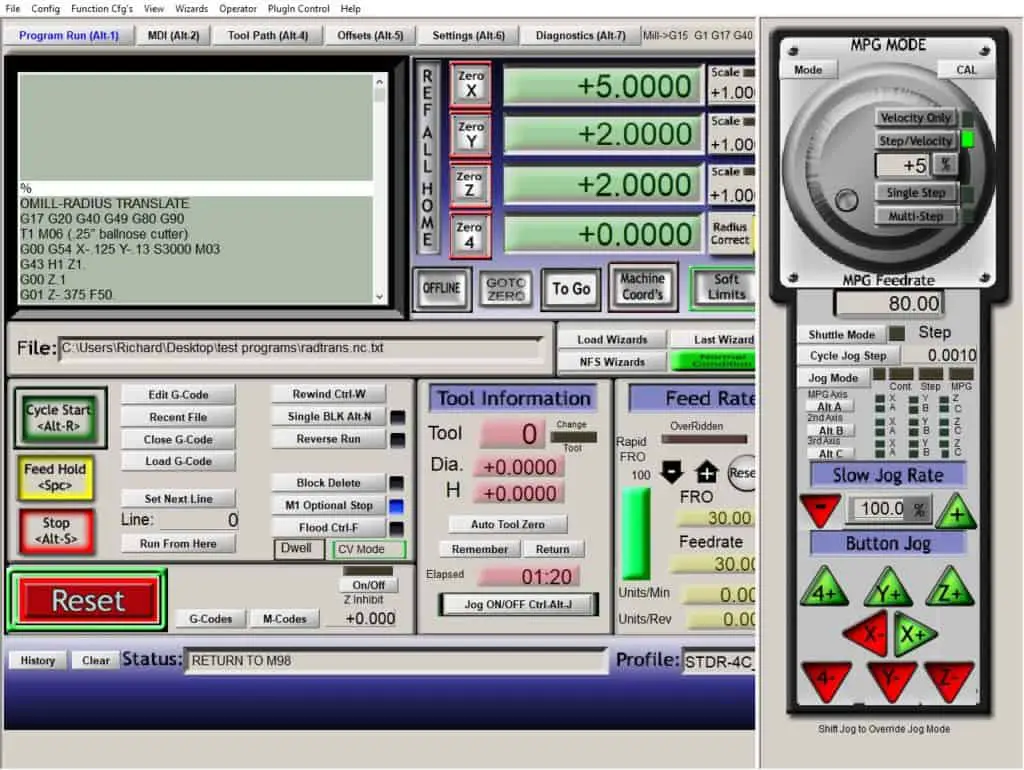

I will explain what most of the buttons do and my opinion on how effective the software is at running a hobby cnc machine. In this tutorial I will be going through all the main screens on Mach3 that you will use to run your G code programs. There is a link at the bottom of this article to a G Code creation tutorial. I should probably explain here that Mach3 software does not create G code programs, it only runs them and sends commands to the machine. Hopefully the following tutorial will answer a lot of questions you may have about using it to run your Cnc Machine. However there are a few quirks that will be different to other cnc control software. If you have run a cnc machine before, but not using Mach3, you will find it quite intuative and really easy use. Well this is a big question that relates a lot to ‘How do I run a cnc machine?’.

#How to use mach3 cnc software upgrade#

So if you have an earlier version that runs well, with no issues, I would advise you to not upgrade to the latest version. One point to note is that updates to this software usually relate to fixing bugs and software conflicts. What is the latest version of Mach3?Īt the time of writing the latest version of Mach3 is V3.043.

#How to use mach3 cnc software windows 10#

I have been using windows 10 for a while and I have had no issues. Cnc enthusiast to control a small milling machine or router. This makes it an ideal option for the D.I.Y. Mach3 is a popular Cnc control software that is available for download to use on windows computers.

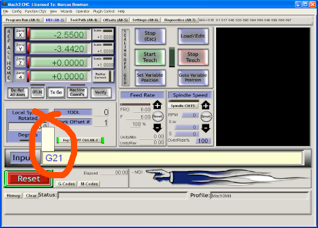

If you would like a set of plans for the Warp Drive Project CLICK HERE.Before I go into detail about the Mach3 user interface with this Mach3 Cnc software tutorial, I want to address a few commonly asked questions about this software. This process only takes a few minutes and will improve the quality of your work instantly. Go into Mach3 and use the Set Steps Per Unit button to do the calculations for you. The basic process involves clamping a yard stick to the rails of your router table. It will walk you step by step through the process. If you don’t feel like spending the rest of the afternoon figuring equations then I suggest you watch this video instead. I don’t plan to prove these calculations but you can feel free to. Mach3 steps per unit = mach3 steps per rev * motor revs per unitĪs you can see there are a lot of things to factor in. Motor steps per revolution 200 step per revolution 1.8 degrees per step. Motor revs per unit = shaft revs per unit* Ns/Nm Shaft revs per unit = 1/(tooth pitch *Ns) Motor revs per unit (MRPU) MRPU=SRPU*Ns/NmĮxample: 8tpi screw connected to the motor with a toothed belt with 48 tooth pulley onthe screw and a 16 tooth pinion the motor shaft pitch would be 8×48/16=24. Screw revolutions per unit (SRPU) SRPU= 1/effective screw pitch The effective screw pitch is the distance the axis moves in one revolution of the screw. Example :(the pitch of an 8 TPI single start screw is 1/8 = 0.125″. Inch screws may be specified by threads per inch ( TPI). You will also need to know the the raw pitch of your leadscrew (the distance from thread crest to thread crest) as well as the number of thread starts.

#How to use mach3 cnc software how to#

In other words you need to know how to calculate the number of revolutions of the motor shaft (Motor Revs per Unit) to move the axis by one unit. In case you are the stubborn type who likes to do things the old school way here are the formulas you need to complete to figure out your steps per unit for your stepper motors.įirst you must calculate the mechanical drive of your system. Figuring out how far your motor has to turn to move a specific distance can be done the old fashioned way using calculations or the easy way, using Mach3. In order to achieve accurate cuts on your 3 axis cnc router table, you must set the steps per unit accurately. Mach3 CNC Control software, CNC tutorials.

0 kommentar(er)

0 kommentar(er)